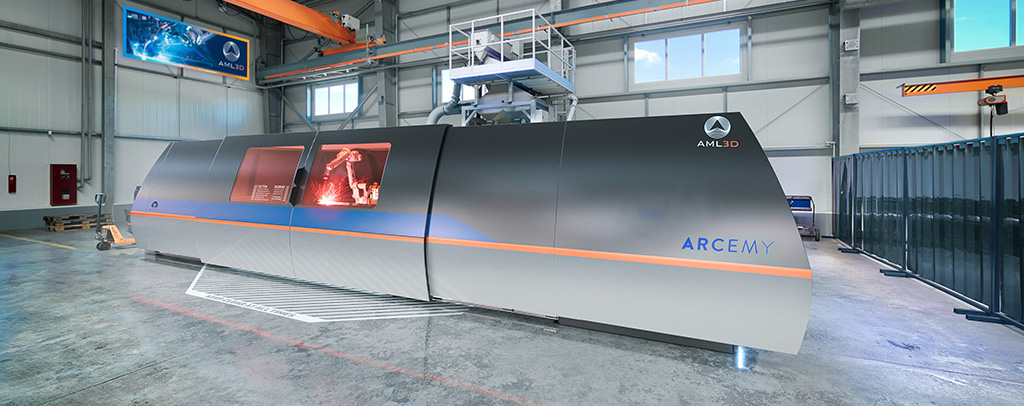

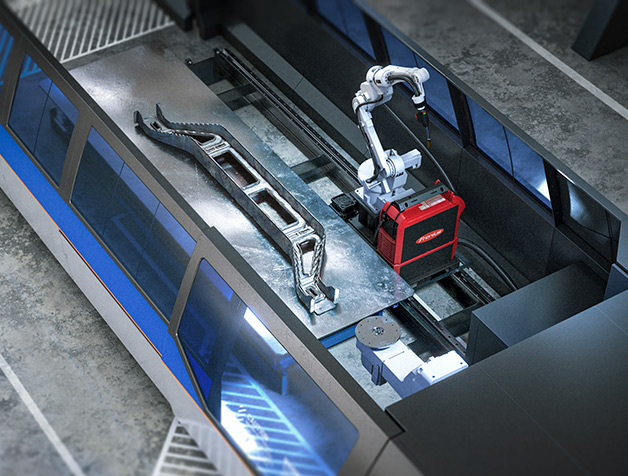

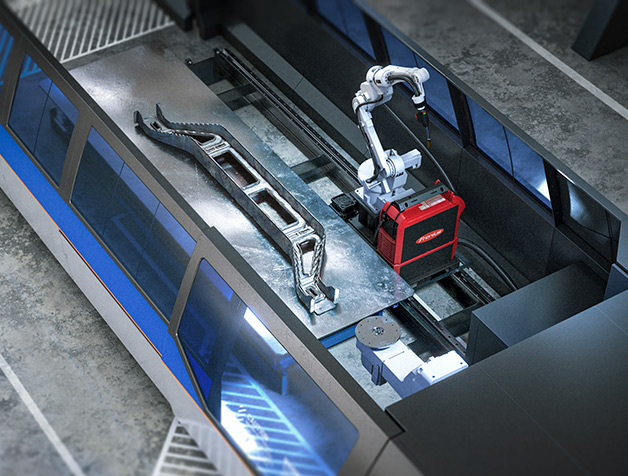

robotic welding module

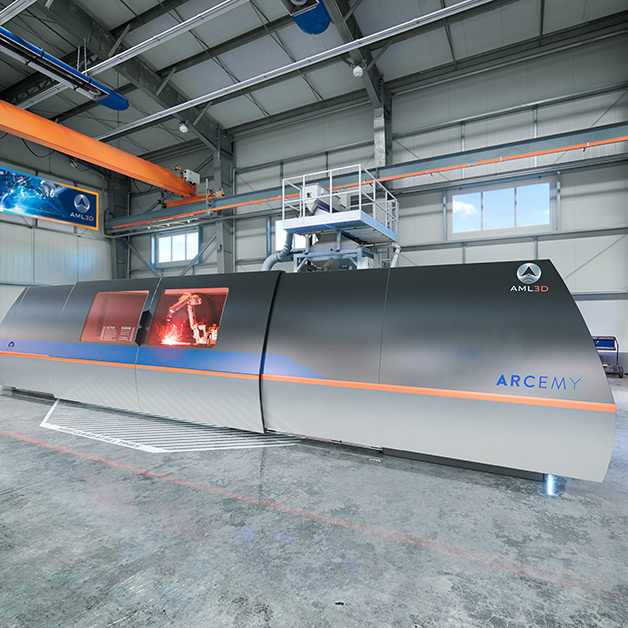

outerspace designers conceptualised how an enclosure for our client AML3D, an additive manufacturing company, would work with their additive manufacturing production line.

Duration

4 months

industry

- safety and industrial

expertise

- industrial design

- mechanical engineering

Working directly with the managing director of AML3D, we helped to define how the module would look and integrate into the existing additive manufacturing production line.

Our design team helped AML3D by visualising the product vision and developing the product design during a business restructuring exercise.

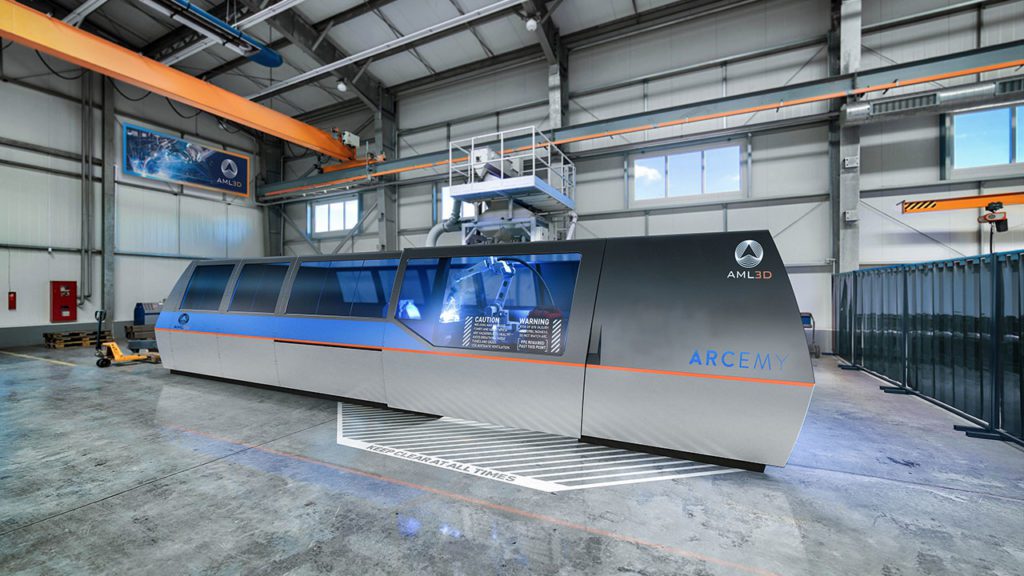

We made it possible for the MD of AML3D to show his product vision to investors, potential customers and other value chain partners. They could see what the module would look like, and how it would successfully integrate.

In addition to designing the enclosure for AML3D, outerspace further assisted by creating an animation to allow the client to better communicate what they were trying to achieve with their product.

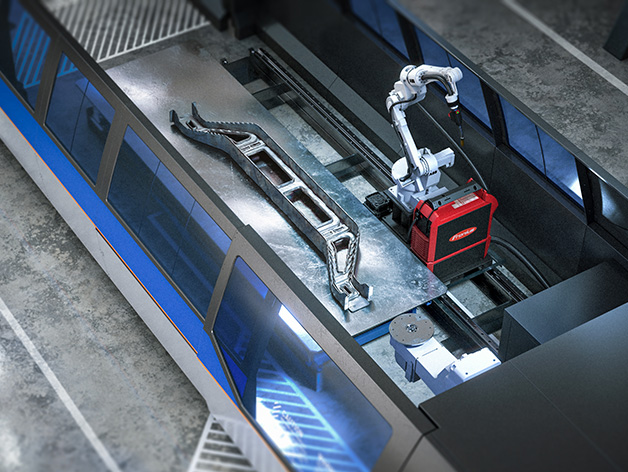

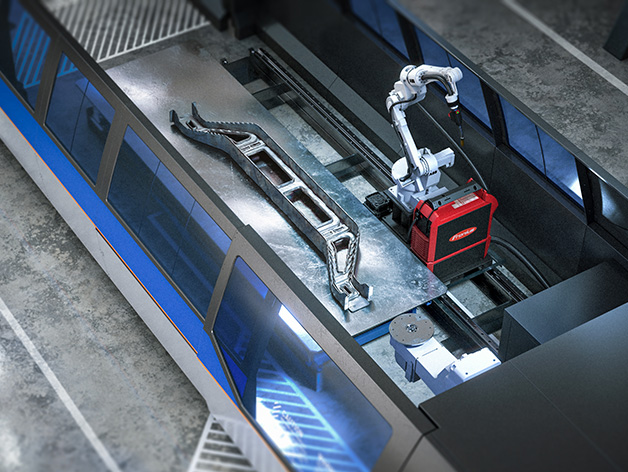

outerspace assisted AML3D to transform what was technically the product into something that looked like a product. Our focus was to encase and merge the robotic welding technology into a production workstation.

We designed the enclosure for their robotic welding module to ensure safety would always be maintained. Included in this were interlocks for the doors and welding safety glass for viewing bays.

Managing Director, Comtruk