outerspace works with a broad range of clients with very specific product development needs. The scientific instrument development market has unique requirements for the combination of both high value and low volume production.

‘Scientific instruments’ is a broad term. The design and engineering capability required to create niche, high-end equipment for specific scientific research activity, commands deep knowledge and an open minded-approach to create state-of-the-art instruments for accurate measurement, monitoring and recording of results and findings.

outerspace assisted researchers from the University of Queensland, Glen Harris and Warwick Bowen with their spin-out venture, Elemental Instruments, to deliver new magnetic field solutions that are transforming these applications across universities and industry.

Harris and Bowen, work at the intersection of quantum technologies, precision sensing, material science and nanotechnology. They founded Elemental Instruments to address unmet needs within research laboratories for instruments that create tunable uniform magnetic fields for magnetic material characterisation and physics experiments.

High strength magnetic fields are used in medical imaging, chemical analysis, material science and particle physics. Traditionally, tunable fields are produced using large electrical currents, requiring bulky power supplies and cooling systems.

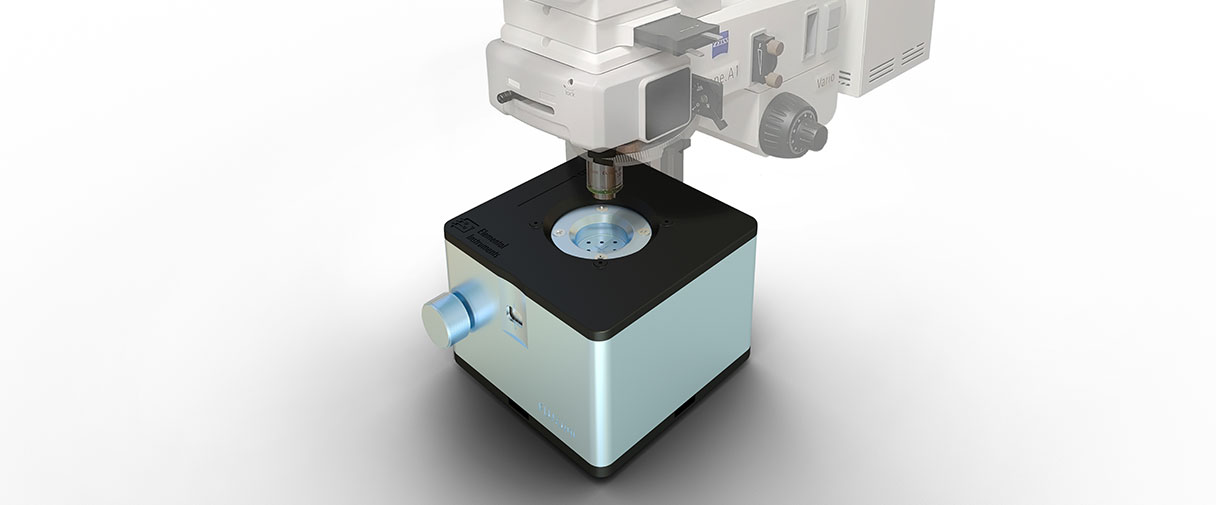

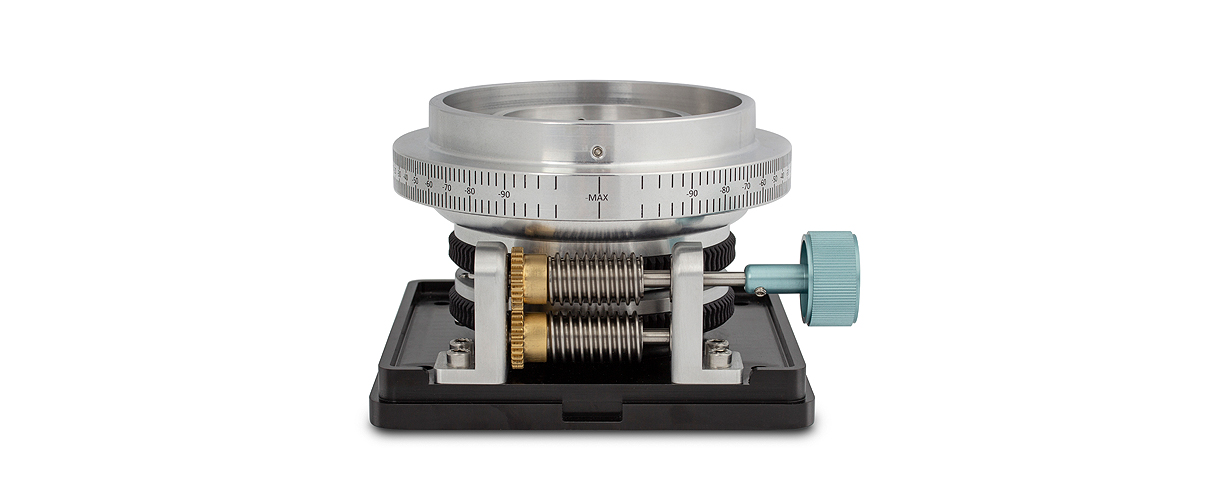

Elemental Instruments had an idea for a compact alternative approach to create these fields by using a special configuration of permanent magnets. They needed a simple, high-quality and robust instrument format for their configuration that was compatible with an upright laboratory microscope.

The new instrument design had to align with their aspiration to deliver new magnetic field solutions that transform applications across universities and industry.

outerspace designers and engineers collaborated with Harris and Bowen, took their core concept and created Flux.

“The team at outerspace played a critical role in transforming our conceptual idea into a commercially viable product. They provided prototyping that was fast and efficient, enabling us to get products to our early adopters as quickly as possible,” says Glen Harris, co-founder and director, Elemental Instruments.

Engineered for low volume production, Flux is the first configuration of Harris and Bowen’s original idea. As it is rolled out to the market, Elemental Instruments has plans for other models and configurations as market interest builds and they scale up to meet demand.

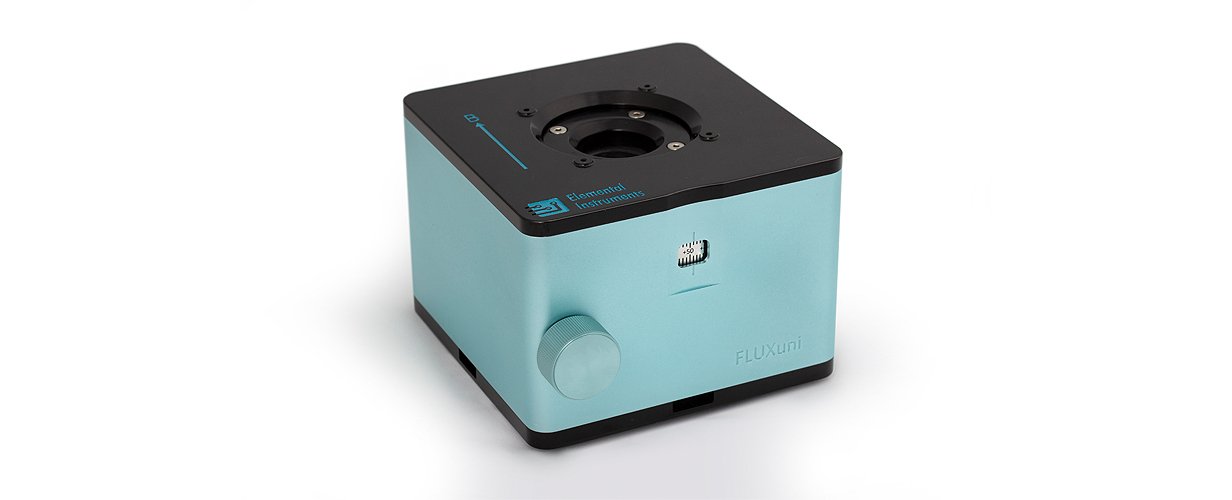

Flux is precision engineered to offer high performance tunable fields in a compact benchtop instrument format. It’s the size of a lab technician’s lunchbox. The small and ergonomic design, weighs only 6.5 kg – a uniquely lightweight instrument. It requires limited or no power with no need for cooling.

Flux is used in magnetic material characterisation, wafer testing, spintronics, quantum spin technologies, nuclear magnetic resonance and magnetic field control in research labs.

Access is provided through the device to mount other scientific instruments such as microscopes, mirrors, diamond microscopes (quantum spin technologies) and nuclear magnetic resonance equipment.

We worked closely with Elemental Instruments to translate their research and early idea and to get their product designed, prototyped and produced quickly and effectively in a very short space of time.

Our team helped them to refine the balance of their specific requirements and to deliver a unique product at a competitive unit cost, with stunning looks and great functionality. Flux performs the same functions as competitor instruments at a much lower overall cost.

fast scientific instrument development

‘Scientific instruments’ is a broad term. The design and engineering capability required to create niche, high-end equipment for specific scientific research activity, commands deep knowledge and an open minded-approach to create state-of-the-art instruments for accurate measurement, monitoring and recording of results and findings.

outerspace assisted researchers from the University of Queensland, Glen Harris and Warwick Bowen with their spin-out venture, Elemental Instruments, to deliver new magnetic field solutions that are transforming these applications across universities and industry.

Harris and Bowen, work at the intersection of quantum technologies, precision sensing, material science and nanotechnology. They founded Elemental Instruments to address unmet needs within research laboratories for instruments that create tunable uniform magnetic fields for magnetic material characterisation and physics experiments.

High strength magnetic fields are used in medical imaging, chemical analysis, material science and particle physics. Traditionally, tunable fields are produced using large electrical currents, requiring bulky power supplies and cooling systems.

Elemental Instruments had an idea for a compact alternative approach to create these fields by using a special configuration of permanent magnets. They needed a simple, high-quality and robust instrument format for their configuration that was compatible with an upright laboratory microscope.

The new instrument design had to align with their aspiration to deliver new magnetic field solutions that transform applications across universities and industry.

outerspace designers and engineers collaborated with Harris and Bowen, took their core concept and created Flux.

“The team at outerspace played a critical role in transforming our conceptual idea into a commercially viable product. They provided prototyping that was fast and efficient, enabling us to get products to our early adopters as quickly as possible,” says Glen Harris, co-founder and director, Elemental Instruments.

Engineered for low volume production, Flux is the first configuration of Harris and Bowen’s original idea. As it is rolled out to the market, Elemental Instruments has plans for other models and configurations as market interest builds and they scale up to meet demand.

Flux is precision engineered to offer high performance tunable fields in a compact benchtop instrument format. It’s the size of a lab technician’s lunchbox. The small and ergonomic design, weighs only 6.5 kg – a uniquely lightweight instrument. It requires limited or no power with no need for cooling.

Flux is used in magnetic material characterisation, wafer testing, spintronics, quantum spin technologies, nuclear magnetic resonance and magnetic field control in research labs.

Access is provided through the device to mount other scientific instruments such as microscopes, mirrors, diamond microscopes (quantum spin technologies) and nuclear magnetic resonance equipment.

We worked closely with Elemental Instruments to translate their research and early idea and to get their product designed, prototyped and produced quickly and effectively in a very short space of time.

Our team helped them to refine the balance of their specific requirements and to deliver a unique product at a competitive unit cost, with stunning looks and great functionality. Flux performs the same functions as competitor instruments at a much lower overall cost.

authors

BROWSE THE TEAM

Belinda Stening

stay connected

subscribe to our newsletter and receive regular updates